Technology

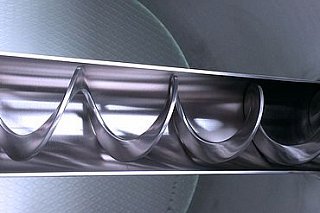

The sampling screw, which projects into the material flow, takes a representative product cross-section from the product flow and conveys it into a sample container. The sample quantity is determined via an adjustable timer, for example. The run and pause times between two samplings can also be freely adjusted. Before each sampling, the screw is run backwards for self-cleaning. The product conveyed during the self-cleaning phase is fed back into the production flow. Sealing takes place via various systems such as a stuffing box or a shaft ring seal. The use of a counter bearing is recommended for gentle product handling.

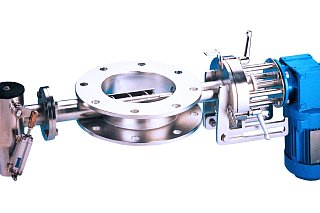

- Downpipe installation: The sampler is screwed between two flanges in a downpipe.

- Silo installation: The sampler is screwed to a nozzle that is welded to the wall of a silo.

the use of an outlet closure (flap, ball valve or pinch valve) prevents the product from trickling or dusting out when the product container is not connected. HECHT offers various connections depending on the sample container:

- Spring steel wire clamp (for light, small sample quantities)

- Torque bag clamp (for heavier, larger sample quantities)

- Threaded connection for bottles