Closed Solid and Liquid Discharge in the Chemical Industry

An industrial customer from the chemical production sector processes very different raw materials in small and medium-sized batches.

The challenge lies in sensitive and sometimes reactive media, because powders react to dust explosions or expose operators to a high health risk. Furthermore, liquids can release aggressive vapours that directly attack metallic components. At the same time, the operator expects a high degree of flexibility, as there are frequent product changes and both solids and liquids are processed.

HECHT has developed an integrated system solution for these applications. The aim is a safe and efficient material flow from containers of various types into a downstream reactor. The entire process is completely closed and inertised. This ensures maximum protection for the operator, product and system environment.

Process Description

Drum emptying with the HECHT CFE-K drum discharging station

To begin with, drums are the most common container format. These are picked up mechanised, fixed and tilted into a working position for discharging. The centrepiece of the station is the functional principle of the HECHT CFE-K: this emptying station is an established solution in the chemical and pharmaceutical industry and is designed to discharge powdery media with an inliner safely and with low contamination. During operation, the drum liner is attached to the EC port. The ergonomic design ensures that the operating personnel work without direct product contact. The transfer into the system remains closed during the tipping process so that even critical substances classified up to exposure class OEB 5 are processed safely.

Further advantages during operation: The drum change is fully supported by pneumatic movements. The operators therefore avoid dangerous incorrect postures. The throughput rate remains constant even with different powder flow properties, as the product is fed directly into the glovebox or hopper. The interface between the drum and the process is held securely and can be visually monitored at all times.

Sack discharging process under inertization

Many products are delivered as bagged goods. They are first fed into the glovebox via an airlock. A defined pressure and inertisation equalisation takes place automatically. The operator then opens the bagged goods using glove ports within a closed atmosphere. Following, the product falls directly into the feed hopper and is shielded from the air and environment. Due to the fact that the finest particles do not enter the work area, the system is ideal for sensitive or toxic solids, which may only be handled in a closed protective atmosphere.

Metal-free liquid discharge in a plastic glovebox

Some of the raw materials are present as liquids and contain highly reactive media. These substances react immediately with metallic components and would cause corrosion, erosion or even malfunctions. For this reason, the second glovebox for discharging liquids is completely metal-free and only glass and special plastics form the interior.

The containers enter the glovebox, which is also inerted, via an endless liner port. Now the liquid is emptied into a glass cylinder and transferred to a target container by means of nitrogen overpressure. The entire discharging process is emission-free so that operating personnel remain protected from splashes or vapours. The glass surfaces can be easily cleaned without leaving any residue and guarantee a long service life and reproducible product safety.

Solids Transport, Inertisation and ATEX

Pneumatic Conveying Process

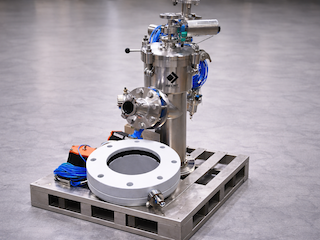

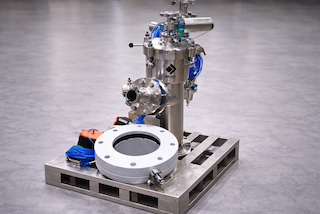

The solids from the feed hopper of the combi box are transported by means of a pneumatic conveyor system. The HECHT ProClean Conveyor PCC in size PCC200 is used here. This transportation system is designed for closed conveying and works reliably in clean room environments and in areas that have to be inertised. The filter head is a key quality feature due to the fact that the filter surface ensures a constant air flow. Dust remains in the separator container. Automatic cleaning via short bursts of nitrogen keeps the filter clear and prevents losses in conveying capacity. The PCC200 also processes products with a high residual moisture content or sticky properties. At the same time, cleaning between product changes remains quick and easy. HECHT systems are equipped with a WIP function and enable the system to automatically rinse the interior and remove possible residues.

Vapour barrier and interface to the reactor

There is a vapour barrier between the PCC and the target tank which blocks the rise of moist or vapoury media from the reactor into the PCC. This measure prevents caking, condensate formation and corrosion. At the same time, explosion protection is supported, as no flammable vapours can rise. The product leaves the PCC in a defined manner via the vapour barrier into the target container and is then transferred to the reactor. The safe interface and the completely closed material flow ensure consistent product quality and high process stability.

Inertization, Safety, and ATEX Concept

The entire process operates under a nitrogen atmosphere. Inerting protects reactive products from oxidation while simultaneously reducing the explosion risk associated with dusting powders and potentially ignitable gases. ATEX refers to the European requirements for equipment and operation in potentially explosive atmospheres and defines, among other things, zone classification and the necessary protective measures. For use in such areas, the overall system is designed in accordance with ATEX and zoned accordingly. Inside the system, Zone 1 and Zone 21 are defined, with the design taking into account highly ignition-prone atmospheres in groups IIC and IIIC. The surrounding outer area corresponds to Zone 2 and Zone 22. The installation is continuously monitored. Exhaust air is controlled and safely routed through a water scrubber, where residues and vapors are reliably captured and separated. This ensures operator protection, plant safety, and environmental protection at all times.

Overall Benefits for Chemical Industry Operators

- One system for solids and liquids with high flexibility for product variants

- Closed process flow from container to reactor

- Continuous operator protection and highest containment requirements

- High efficiency through ergonomic handling and automatic cleaning

- Operational safety through inertization and a defined ATEX strategy

- Quality assurance through reproducible processes and stable conveying

- Future-oriented design through modular construction and easy scalability

The customer benefits from a solution that measurably increases product safety, occupational health, and productivity. At the same time, the system remains prepared for future raw materials, regulatory requirements, and expanded process steps.