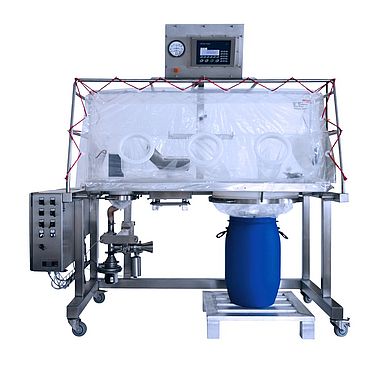

Safe and contamination-free dosing, sampling, (re-)filling and weighing of small quantities of highly active or hazardous substances is only a small choice of customer specific operations that can be performed with HECHT's Single-Use Isolator (EWI). The EWI is a flexible, completely closed foil system operatable with gloves. It guarantees operator and product protection due to the use of a flexible foil and different customized connection adapters for various kinds of bins (drums, sacks, cartons, etc.) There is no need for a time-consuming cleaning or cleaning validation.

Depending on the use case, the number of ports for loading and unloading, the connection of the gloves for the operation of dryers, blenders, granulators etc. will be determined according to your customized needs.

One special option for the EWI is our patented weighing system. The active weighing technology is located outside of the isolator so there is no danger of contamination. Only the scale pan is mounted in the inside. It is possible to weigh in different bulk solids to a minimum weight of 2 grams.

Safety

- Primary Containment due to protective foil

- Safe (re)filling and weighing in of small quantities

- Operator and product protection due to negative and positive pressure

- Leakage test for every foil isolator

- High Containment-OEL: up to 1µg/m³ (OEB5) - within the laminar flow cabine: up to 200 ng/m³(OEB6)

- No cross-contamination

Cost Efficiency

- Low investment and maintenance costs

- Hardly and costs for cleaning and validation

- Short changeover time

Flexibility

- Adaptable to different kinds of bins and applications

- Process control can be adapted to OEL-requirements

- Inertisation (optional)

- Mobile and location-independent

- Quick product change due to single-use technology, short setup times

- Different bins with liners useable

- Various foil isolators within one frame individually designable

The system is diveded into a fixed permanent element and a flexible part. The permanent part consists of a stainless steel frame which includes the working surface with dedusting unit as well as the intake for the single-use isolator.

The control unit is customized according to the OEL-requirements and can be operated in a simple underpressure mode with or without inertisation.

The EWI can handle different process methods and there are various ports available for different customized manipulations like magnetic stirrers, weighing systems, feedthroughs for power and air supply etc.

Depending on the process requirements, any number of loading and unloading ports as well as gloves can be integrated. All versions are built in GMP-compliant design.

The flexible part consists of the single-use foil isolator (material PE, PU, conductive) which can be simply and quickly mounted to the permanent frame. Depending on the customer's requirements, there are various designs possible and it is possible to combine different single-use isolator systems in one station. All surfaces in contact with the product are compliant with the respective pharma and food relevant requirements.

Product handling takes place via gloves inside the isolator. The single-use foil is mounted into the fixed frame and all interfaces will be connected. A pneumatic seal or a vacuum plate for stabilisation of the isolator are activated and the system is ready for operation.

The bins with the product are either connected to an inlet port or directly infiltrated into the isloator. With the pneumatic seal in the counter ring, the outer liner is fixed to the connecting port and the product handling can be started. The operator opens the foil system with the integrated gloves and removes the product through the inner liner. Both the isolator as well as the connected bins stay completely closed and contained. As soon as the process step is finished, the bin is removed with a double tie-off and cut-off of the foil, whereby both the isolator and the bin stay completely closed. After deactivation of the pneumatic seal, the foil isolator can be removed and a new cycle can start without delay. After the product handling is finished, the isolator can easily be disposed without any further action in terms of cleaning or decontamination.

The EWI is especially suitable for handling small bins or for processes that demand handling with 2 liners. Due to its small size, the complete station is flexible and mobile. Only electronic supply (230 V) and compressed air supply are necessary.