HECHT cares.

Our services

Discover how we can reliably support you with expertise, personal commitment and customised services.

With a holistic view of processes, systems and people, we create solutions that stand the test of time and are convincing in the long term.

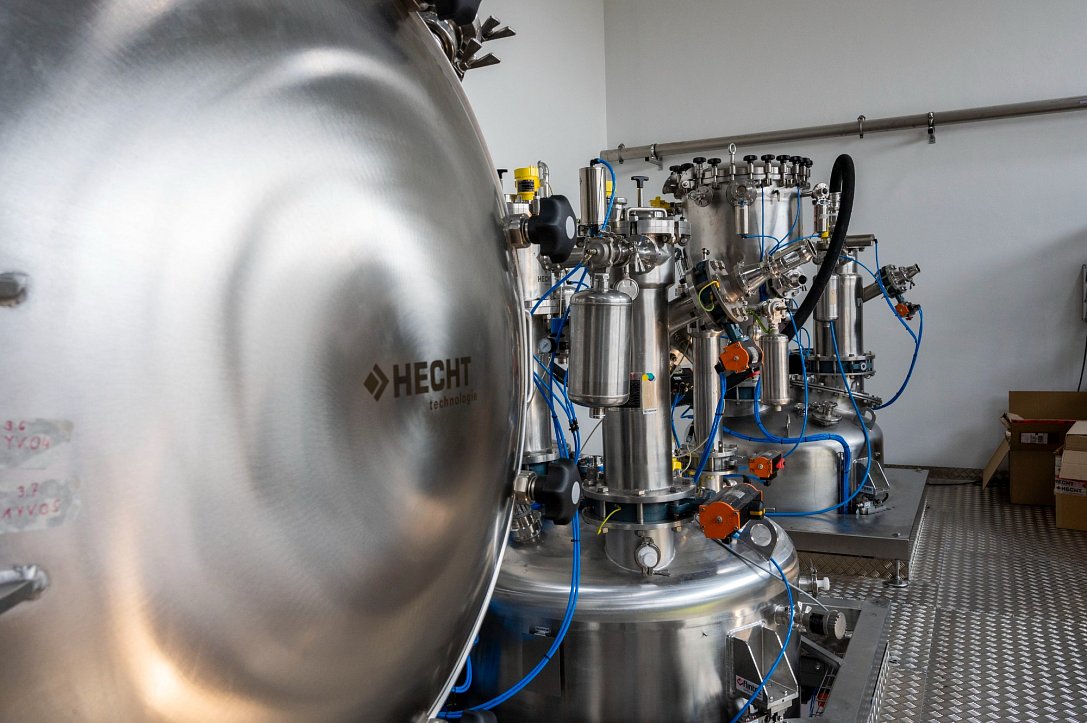

Tests in the HECHT technical centre

The HECHT technical centre offers the right environment for a wide range of tasks in bulk materials handling. We realise practical tests for you quickly and cost-effectively. Visit our HECHT showroom and our neighbouring technical centre and see for yourself.

You can test the following procedures with us:

- Emptying

- Filling

- Conveying

- Crushing/shredding

- sieving

- Dosing/ Weighing

- Containment applications

- CIP/WIP cleaning incl. riboflavin test

Our scope of services for customer trials:

- Test preparation for smooth, time-saving test processing

- Test set-up incl. mechanical adjustments, if necessary preliminary tests

- Material handling

- dispatch handling

- Energy costs

- Test execution

- Cleaning the systems

- Preparation of a detailed test report

- Storage of test material

Inspections

By inspecting your systems at an early stage, we reduce the follow-up costs for maintenance and servicing. This extends the reliability and service life of your systems in the long term and ensures that they remain ready for production.

Any inconsistencies can be recognised at an early stage and rectified during the next maintenance. Systems are checked mechanically, electrically, pneumatically and hydraulically as required.

Our inspections also serve to discuss a comprehensive supply of spare parts. We also discuss optimisation options with you and are happy to provide you with training recommendations for handling the machine. In this way, we guarantee the safety of man and machine. We care.

Maintenance and servicing

A holistic view of the production conditions and tasks of your systems as well as the value retention of your capital goods is a matter of course for HECHT. Customised regular maintenance of HECHT systems at the customer's premises is one of our main services. We customise these to your system. According to defined maintenance intervals or at your request, we ensure a comprehensive and smooth implementation at your site. You will of course receive a detailed report of the work carried out. We will be happy to draw up the appropriate maintenance contracts with you, create checklists for the individual products and assemblies and provide you with recommendations for spare parts. We can also organise training courses for minor troubleshooting.

Assembly

Our experienced HECHT service technicians are at your disposal for the professional installation of your systems. The systems are installed efficiently and on schedule according to a defined plan. Assembly activities, time sequences, interfaces and other necessary documents and tools are meticulously planned in advance during the project phase. In addition to the mechanical and electrical installation, our service team supports you from the qualification process through to the final commissioning, if desired, together with the customer.

FAT/SAT

In addition to pure mechanical and electrical assembly, a defined qualification process for the systems is the current standard for most customers. This process usually involves several stages and acceptance phases. In addition to the DQ (Design Qualification) including the release of approval drawings, FAT (Factory Acceptance Test) or SAT (Site Acceptance Test) are common components of a qualification. Other components may include IQ (Installation Qualification) or performance runs to determine process parameters. We will be happy to determine the exact components of the qualification process together with you.

If necessary, we will carry out a mock-up in advance to find a solution. This involves manufacturing components quickly and easily from wood. We also use wooden frame constructions for FATs so that your system can be accepted as closely as possible to the production conditions.

FAT - Factory Acceptance Test

The FAT of a new HECHT system is an optional part of our qualification process. Thanks to our testing, you can be sure that your investment meets your expectations exactly. Depending on the agreement and contract, a FAT can be carried out with or without a functional test. The acceptance of your system is carried out according to precisely defined acceptance criteria. Each test is based on the specifications of the functional specification and, if necessary, further modifications or adaptations of the HECHT systems agreed when the contract was concluded. The FAT usually takes place without the product. After successful acceptance, the systems and equipment are packed and prepared for despatch in accordance with the despatch specifications.

SAT - Site Acceptance Test

The SAT of a HECHT system is also an optional part of our qualification process. Essentially, the SAT is part of the IQ. In addition to the documented proof of professional mechanical and electrical assembly, the functionality of the systems is checked and also documented. Furthermore, I/O tests or software tests can be carried out. After a successful SAT, the first test runs are carried out with the test product or the actual product. Only then are performance runs with actual production parameters carried out and recipe management is supported.

Leasing

The acquisition of new machines or technical systems in companies usually involves large investments and the purchase of those systems, which are either financed by equity or loans. Once the loan has been paid off after many years, the existing technology may already be outdated. Leasing systems and equipment offers the opportunity to stay economically up to date and reduce high initial investment costs. This is a worthwhile alternative to outright purchase. A large part of your company's capital remains free and can be used for other investments. HECHT offers lucrative conditions for leasing almost all equipment and systems from our product portfolio. The instalments are clearly defined in the leasing contract, and at the end of the contract you decide which option is right for you:

- Purchase of the system

- Simple contract extension