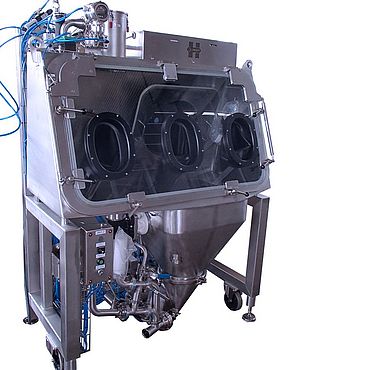

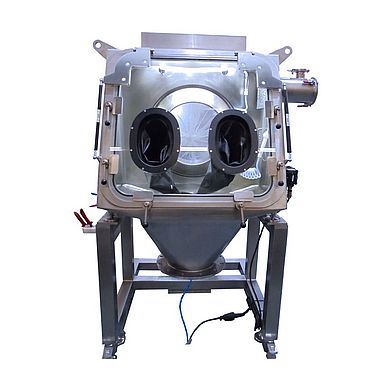

HECHT's Containment Drum Discharger CFE-K-EC with tipping device and "Easy" port is used for low-contamination discharging of drums with inner liners up to OEB 5. Thanks to the new EC-port which is part of our "Easy Connect" Family, drums can now be exchanged significantly easier and more economic. The new technology enables a drum exchange nearly free of any consumables.

The increased operator convenience and still high Containment conditions are strong arguments for this new technology. By means of the tipping device drums can be connected easily.

The products supplied in drums are additionally packed in foils, also referred to as liners, to ensure operator- and product protection.

- Safe Discharging of drums up to OEB 5, OEL < 1µ/m³

- Observation of the product flow

- Product handling by means of gloves for easy handling

- Simple and contamination-free exchange of the gloves

- Higher degree of automation due to the new EC-port

- Exact positioning and docking of the drum with guide rails

- Discharging of different drum Diameters

- Further transportation via downpipe or downstream conveying (pneumatic)

- WIP integration possible

- Nitrogen purging

- Hygienic- or ATEX design possible

- Optional empty sack disposal

- Various surfaces and materials

- Significant reduction of consumables

- Quick, simple and safe handling

- Drum is lifted at the backside of the glove box using a special tilting and lifting device

- Drum is attached to the provided connection port

- Remaining liner seals the glove box in the initial position

- Operator fastens the outer liner tube to the double O-Ring port of the isolator via the remaining liner

- Operator pulls the remaining liner into the isolator using the gloves

- Clamping ring is fastened to the outer groove

- Open drum is drawn into the isolator

- Inner liner is emptied using the gloves

- Bulk material is transported by gravity to the next process step

- Optional suction shoe can be mounted at the bottom outlet of the glove box for vacuum conveying

- Liner tube seals the drum and isolator with a special double closure system after discharging

- Double-closure system protects both the isolator and the product from unwanted product escape or entry

- Cycle restarts and a new drum can be connected