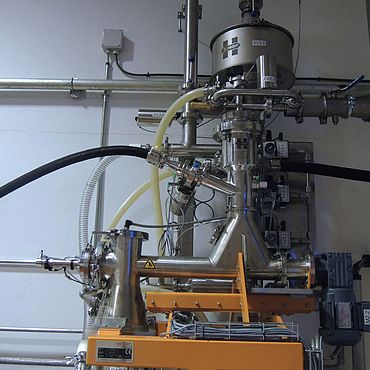

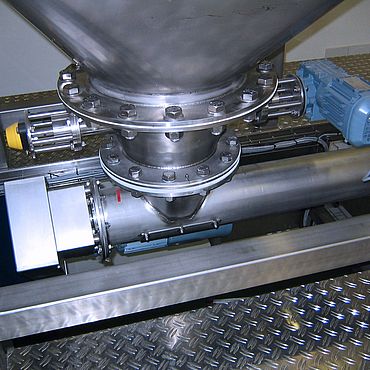

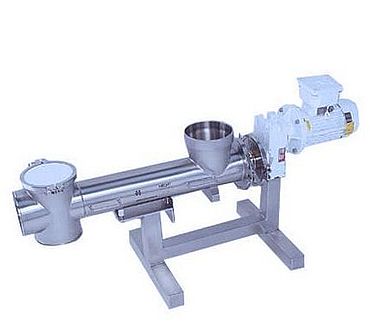

HECHT auger feeders are particularly suitable for feeding free-flowing bulk materials. In the case of poorly flowing bulk solids, a discharge device ensures uniform feeding of the product. Depending on the application, volumetric or gravimetric systems can be used.

- Quick dismantle version (optional)- fast removal of the screw for cleaning and inspection

- Outlet sealing (prevents trickling of the product after dosing has been completed)

- Gland box or air seal

- Version with Explosion protection

- Different materials on request

- Various sizes depending on the application

- Volumetric or gravimetric

- Simple integration of process systems

- Versions in hygienic design

- Dosing screws can be used volumetrically or gravimetrically depending on the bulk material and application

- Substances and granulates with good flow behavior are suitable for volumetric dosing

- Flow rate is regulated by the rotation speed of the screw

- Dosing capacity depends on the flow rate conveyed per time unit, based on the rotation speed

- For loss-in-weight dosing with a fixed, documentable nominal value, gravimetric dosing is recommended

- Gravimetric dosing is combined with a weighing and control device

- Mass flow is controlled and measured through weight control