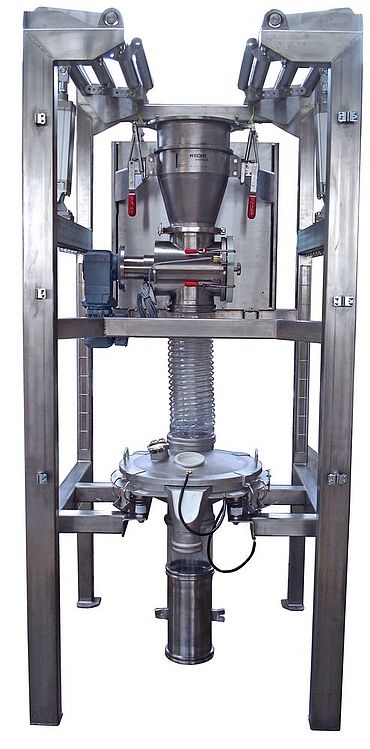

HECHT's easy-to-clean rotary feeder is particularly suitable for frequent product changes. It is a dosing device for various filling stations or loading points for screening machines, especially for food or pharmaceutical applications. The ease of cleaning is an enormous advantage where frequent product changes are required.

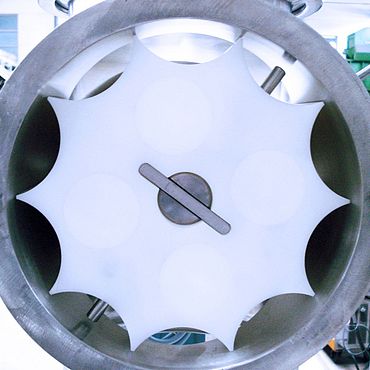

- The rotor is made of synthetic material and therefore very light

- Easy dismounting without tools

- Various rotorgeometrics and axis

- For Ex-zones applicable

- Hygienic shaft seal

- The single-edged bearing of the rotor makes it easy to dismount the rotor

- All surfaces that are in contact with the product are FDA compliant

- Easy to clean

- Rotor transfers a specific product quantity from the product inlet to the outlet

- Ensures controlled and precise dosing

- Product flow is controlled by adjusting the rotational velocity

- Magnetic safety sensor prevents rotor operation when the lid is opened