Handling LBK-EC

Um sich an dieser Stelle das eingebettete YouTube Video anzeigen zu lassen, müssen Sie der Nutzung von "Externen Medien" zustimmen.

Alternativ können Sie das Video auch hier direkt bei Youtube in einem neuen Fenster öffnen.

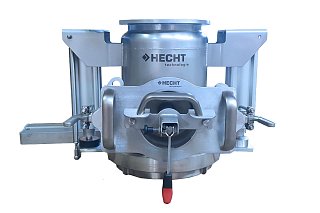

The LBK-EC "Easy Connect" liner filling head is the optimum filling solution for drums and big bags under containment conditions up to OEB 4. Developed for dust-free filling of containers with inliners, the containment filling head impresses with maximum safety, ease of use and efficiency.

Technology

- Drum is lifted by a special lifting device on the back of the glovebox

- The drum is docked onto the designated "Easy" port

- In the initial position, the glovebox is closed by a residual liner (shower cap)

- Port is opened, shower cap seals the port via a clamping device

- Outer liner is pulled over the liner connection

- Port is closed and the new secondary liner is automatically fixed in place

- Showercap is pulled off via the glovebox

- Drum is pushed into the glovebox and raw material is emptied

- Bulk material is transported to the next process step by gravity

- Optional suction shoe at the end of the hopper can be integrated for vacuum conveying

- After emptying, the secondary liner is tied and separated twice with the HECHT containment closure system

- Sealing technology protects the isolator and product from unwanted product leakage or entry

- Cycle can start again, new drum can be connected