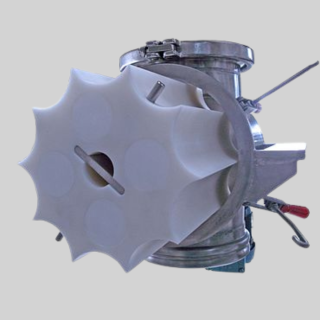

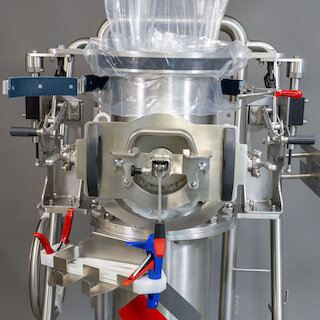

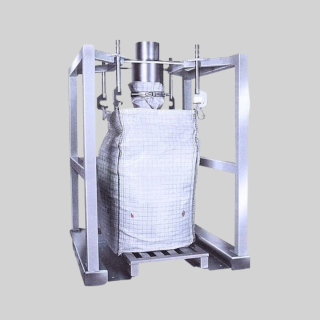

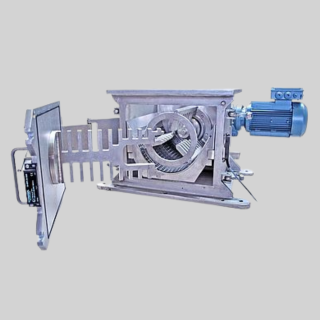

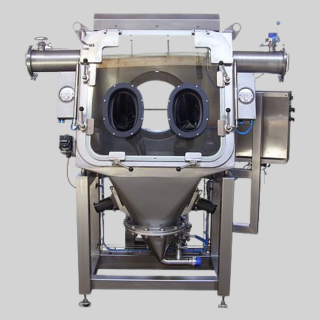

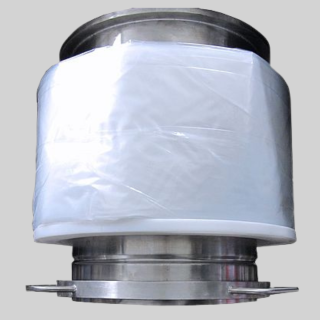

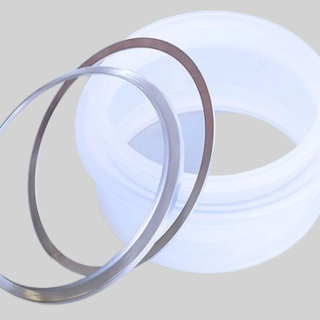

Whether sampling for incoming and outgoing goods inspections, for laboratory tests or other areas of quality assurance: HECHT's innovative disposable sampling system (EPS) enables the sampling of highly active or highly hazardous products from small containers without the need for complex protective and cleaning measures.