Technology

- System consists of a fixed and a flexible part

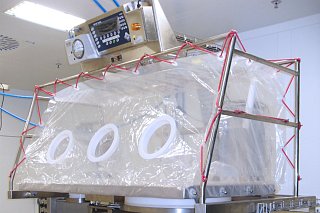

- Fixed part: stainless steel frame with work surface, suction and holder for disposable foil isolator

- Control system adaptable to customer-specific OEL requirements: from simple ventilation to negative pressure operation with or without inertisation

- EWI enables various processes, various port designs for customised manipulations (e.g. magnetic stirrers, weighing systems, power/air supply)

- The number and type of inputs/outputs and gloves are variable depending on the process requirements

- Flexible part: disposable foil insulator (PE, PU, also conductive) is quickly hooked into the frame

- Different versions of the disposable foil isolator possible, all parts in contact with the product fulfil pharmaceutical and food-relevant requirements

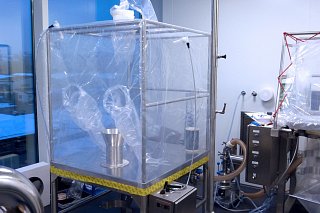

- Product handling takes place via gloves in the disposable film isolator

- Disposable film isolator is hooked in, connections connected, pneumatic roll-out seals or vacuum plate fix it in place

- Packs are inserted or connected to the connection port, outer liner is fixed to the connection port

- Material is removed and processed via gloves, the container and isolator remain closed

- After processing, containers are removed after double setting and separation of the film, both remain closed

- Disposable film insulator can be quickly replaced and disposed of, no cleaning/decontamination required

- EWI is suitable for handling bulk goods from small containers with one or two liners

- Station is flexible, transportable (optionally on castors), requires only electricity (230V) and compressed air (6 bar)